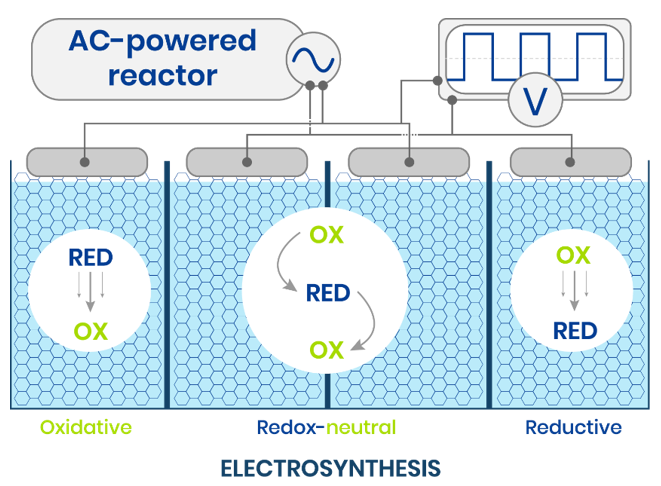

A scalable, stirring-free electrosynthesis method utilizes alternating current (AC) electrolysis to enable efficient redox-neutral, oxidative, and reductive transformations. The AC design periodically switches electrode polarity, allowing oxidation and reduction to occur on the same electrode and throughout the reactor volume. The reactor design maximizes efficiency, selectivity, and suitability for industrial-scale applications.

- Industrial-scale synthesis of chemicals and pharmaceutical ingredients

- Synthesis of viscous solutions or reactions with high substrate concentrations

- High-throughput electrochemical screening

- Scalable and Cost-Effective

- Wide Applicability: Supports a broad range of electrochemical transformations

- Environmentally Friendly

- Enhanced Efficiency and Selectivity

The technology has been demonstrated across multiple electro-synthesis processes, including redox-neutral, oxidative, and reductive transformations. It has been successfully proved for reactions of 50mmol, highlighting its scalability and industrial potential.

Dr. Vered Pardo Yissar