Electrospinning is a common technique for producing ultrafine polymer fibers (of a few microns). However, it is almost exclusively used for thermoplastic polymers. Electrospun fibers of thermoset polymers, which remain stable at high temperatures, could have various applications such as solvent resistance filters and reinforcement in composite materials. However, due to technical limitations, the electrospinning of standalone thermoset polymers such as epoxy fibers has not been possible. Prof. Daniel Wagner and his coworkers successfully created a robust epoxy solution that can be electrospun into fibers in the range of 3-20 µm with relatively low diameter dispersity. Those fibers can be used for ultrafine filters for a wide range of solvents and as a reinforcement for composites.

Fibrous materials tend to exhibit superior properties compared to their bulks. One of the methods to fabricate materials (primarily polymers) is electrospinning, which is used for ultrathin fibers preparation. The resulting electrospun polymers are key materials in filters, medical bandages, and composites, but they all belong to the thermoplastic group of polymers. The ability to produce electrospun thermoset polymers (such as epoxy) will allow gaining properties such as thermal stability and solvent resistance, which is lacking in thermoplastic polymers. As thermoset polymers generally differ from thermoplastic polymers in their mechanical properties (such as Young’s modulus and strength), fibers from such materials will most likely have superior mechanical properties. Therefore, electrospun thermosets (especially epoxy as a low-cost polymer) could replace their relatives in existing applications or be implemented in new ones.

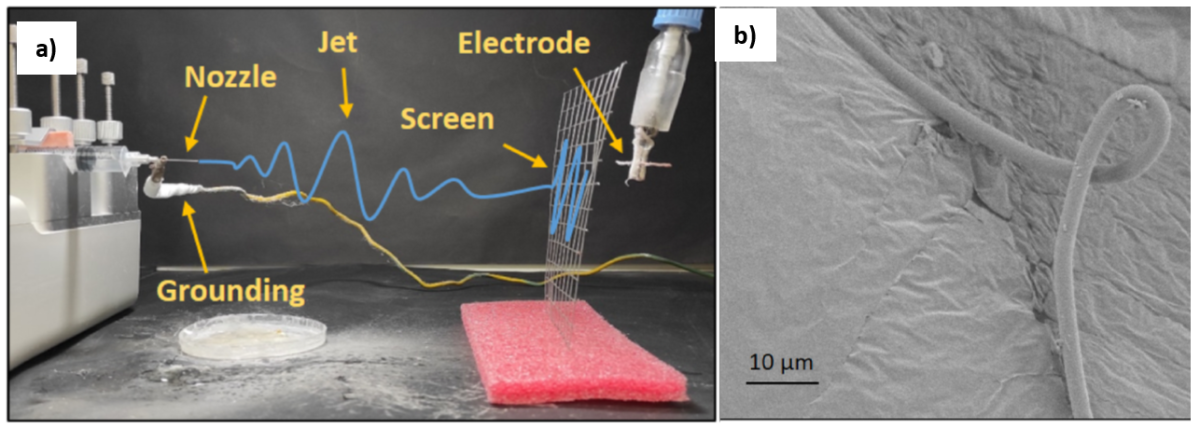

Prof. Daniel Wagner and his team developed a novel method for dissolving epoxy oligomers in methyl ethyl ketone (MEK) to form a suitable solution for electrospinning (figure 1). The resulting epoxy microfibers are later fully cured at high temperatures. The electrospun epoxy fibers show superior behavior compared to the bulk epoxy.1

Figure 1 - a) Electrospinning setup: an epoxy solution is injected through the Nozzle into an electrical field (resulting from the difference in electric potential between the positive electrode and grounded components), then stretched to form a fiber. The fiber is drying in air (jet) and is collected on the screen. b) SEM micrograph of electrospun epoxy fiber.

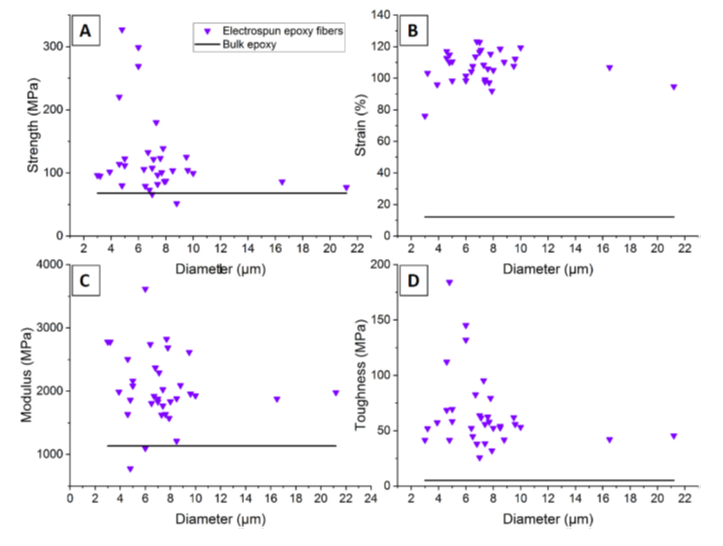

As cured epoxy is a crosslinked polymer, it cannot be dissolved in a dielectric solvent for electrospinning. On the other hand, epoxy monomers are liquids and cannot be spun. In the present method, epoxy is partially polymerized into a gel phase (a low-density crosslinked network) and dissolved in a dielectric solvent (MEK in the present case). With this method, the thermoset polymer can be electrospun. The resulting fibers are then post-cured to reach a fully crosslinked structure. Tensile tests of the resulting fibers show much enhanced mechanical properties compared to bulk epoxy (figure 2).

Figure 2 - Tensile test results: (A) Engineering strength, (B) Maximum strain, (C) Young’s Modulus, and (D) Effective toughness (calculated as the area under the stress-strain curve) versus fiber diameter.

Applications

- Reinforcement for composites

- Filters

- Other applications, including sensors, coating, and electronic devices

Advantages

- Stable behavior of thermosets under high temperatures

- Superior mechanical properties

- Solvent resistance

- Cheap material and technique

M. Shneider, X.M. Sui, I. Greenfeld, H.D. Wagner, Electrospinning of epoxy fibers, Polymer, Volume 235, 2021, 124307, https://doi.org/10.1016/j.polymer.2021.124307