Electrostrictive actuators are devices that convert electrical signals into tiny, precise movements, widely used in medical devices, robotics, and microelectronics. Current gold-standard materials, such as PMN-PT, provide strong performance but have major drawbacks: they contain toxic lead, require high power, are mechanically weak, and are not compatible with silicon chip technology.

This technology presents a new approach using ceria-based electrostrictive materials with specially designed non-blocking contact layers, combining strong actuation with high mechanical strength, low power consumption, and full compatibility with microfabrication processes.

- Medical micro-devices: e.g., miniature insulin pumps and drug-delivery systems.

- MEMS and NEMS actuation: micro-positioning, optical switching, and micromechanical control.

- Industrial actuators: high-precision robotics, aerospace, and automotive systems.

- Replacement for lead-based electrostrictors: eco-friendly alternative to PMN-PT/PZT in sensors & actuators

- Non-blocking contacts: Maintain efficient strain response without interfacial losses.

- Superior properties: High stiffness (>190 GPa) and low dielectric constant vs. PMN-PT.

- Safe & compatible: Lead-free, inert, and suitable for silicon microfabrication.

- Proven durability: Stable actuation (>200 ppm strain) for 100+ hours

- Prototype multilayer stacks fabricated (slurry-casting and co-pressing/co-firing) and validated by SEM, impedance, and strain tests.

- Demonstrated stable strain responses of 200–1000 ppm over 96 hrs continuous operation.

- Pump design studies confirm the feasibility of stack-based electrostrictive micro-pumps, with superior performance over PZT.

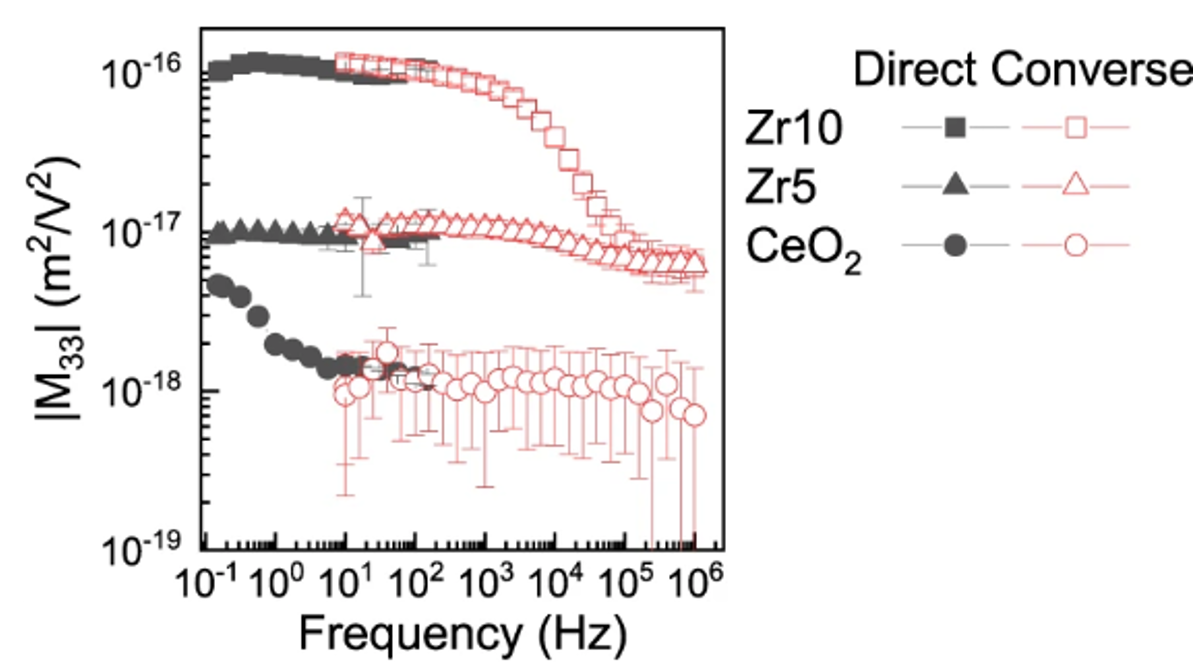

Log-log plot of the absolute value of the converse (VAC=10V) and direct longitudinal electrostriction strain coefficients for undoped ceria and for 5−10 mol% Zr-doped ceria as a function of frequency.

Dr. Vered Pardo Yissar