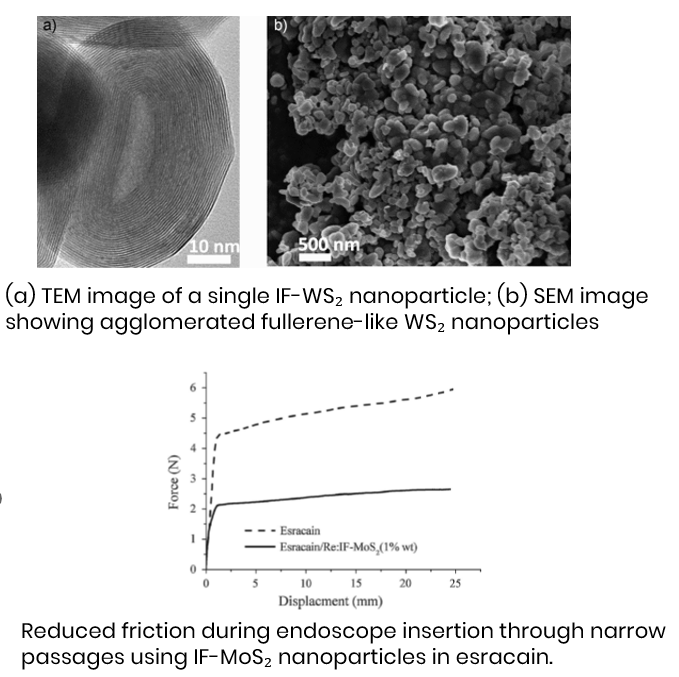

Implantable or insertable medical devices must be made of materials with unique properties in addition to biocompatibility to address potential damage from the physiological environment and to maintain their effectiveness over time. For instance, urethral medical devices (e.g., catheters) are damaged by the encrustation of minerals from the urine, which results in their frequent replacement. Various medical applications suffer from excessive friction, severely compromising their function leading to prolonged treatments. Prof. Tenne and his team developed a novel method for coating medical devices using inorganic fullerene-like nanoparticles to increase their lubricity and prevent encrustation. This coating is applicable for various devices such as stents, catheters, dialysis tubes, cannulas, and sutures.

- Coating for implantable or insertable devices (stents, catheters, dialysis tubes, cannulas, sutures)

- Endodontic files for root canal treatments to reduce friction and file breakage

- Endoscopic and laparoscopic tools for smoother insertion through constricted passages

- Significantly reduces friction and prevents mineral encrustation

- Non-toxic and biocompatible – initial animal studies confirmed safety

- Cost-effective and easily applied to existing medical devices

- Nanoparticle structure (closed-cage, no dangling bonds) ensures exceptional lubricity and stability

Proof-of-concept demonstrated in coated NiTi endodontic files and other metallic substrates, showing reduced fatigue and friction without toxic effects. Further testing in animal models confirmed biocompatibility.

Dr. Vered Pardo Yissar