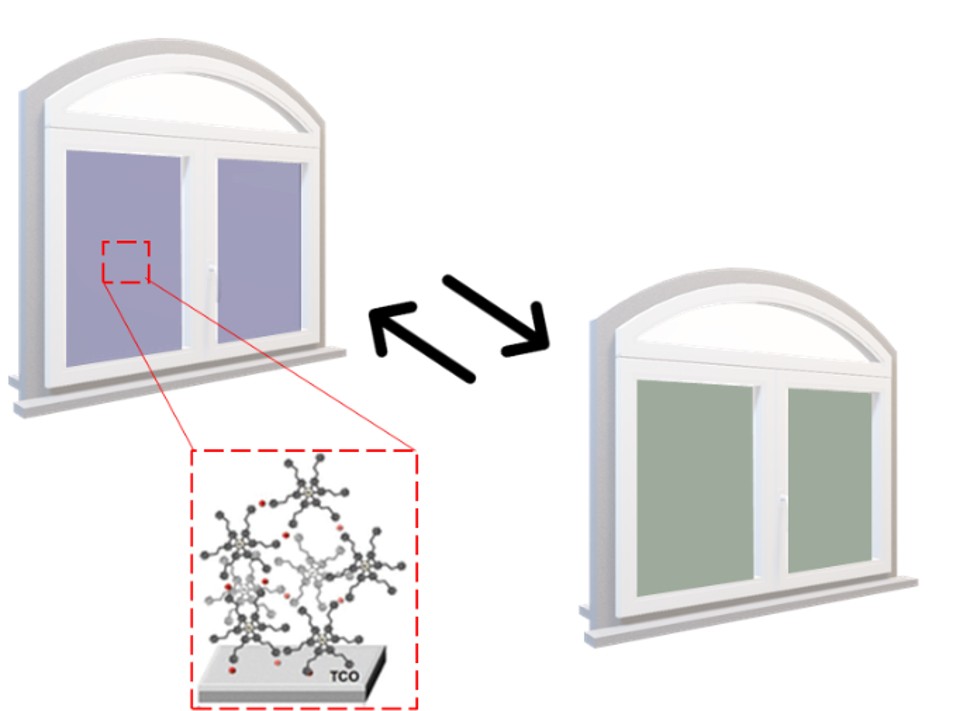

Current electrochromic materials offer a broad color range and moderate electrochromic activity. However, real-world applications demand more intense coloration, faster switching times, and improved stability. To address these needs, new electrochromic materials have been developed and integrated into an optimized, fully automated spray-coating process for smart, color-changing surfaces. This controlled synthesis and coating method enables precise tuning of color palette, intensity, and reversibility, ensuring rapid response times and high color-switching efficiency. These advances position the technology as a strong candidate for high-performance electrochromic devices.

- Smart color-changing glass (windows/glasses/mirrors/windshields etc.)

- Color displays

- Electrochromic lenses and helmet-visors

- Wearables devices

- Electrochemical sensors

- Fully reversible optical responses

- Very high coloration efficiency

- Color tuning by synthetic means

- Automated spray-coating process

- Fast response times (~400 ms for >95%)

Electrochromic materials with a diverse color palette were demonstrated on a 6×6 cm surface and integrated into an efficient, fully automated spray-coating process, enabling enhanced coloration control.

Dr. Vered Pardo Yissar