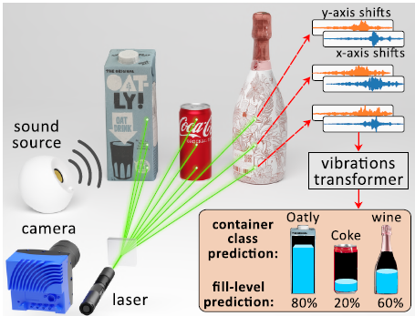

A novel AI-powered imaging technology that accurately determines fluid levels in opaque containers. It employes a speckle-based vibrational imaging system using a cost-effective camera-laser system and a deep learning-based inference. Unlike traditional, costly methods such as Laser Doppler Vibrometry (LDV), this solution offers scalability, ease of deployment, and cost-effectiveness. It addresses significant market demands for precise, simple, and non-invasive fluid monitoring across various industrial applications.

- Building and infrastructures: Structural monitoring and fault detection.

- Food, beverage, and pharmaceutical industries: Non-invasive fluid level checks, authentication & contamination detection.

- Industrial and manufacturing: Hazardous Leak detection, packaging integrity, real-time production quality assurance.

- Healthcare diagnostics: Remote monitoring of physiological signals (pulse, blood pressure, breathing).

- Potential survivor detection in disaster zones.

- Simultaneous 2D grid scanning, high speed & accuracy

- Cost-effective & scalable

- Advanced AI-based inference

- Adaptable to varied fluids, containers, and sensing tasks

- Quick and simple

The technology has been demonstrated for fluid level detection in opaque containers using multi-point vibration sensing in laboratory settings. Hardware and transformer-based AI components thoroughly validated, with ongoing research aimed at expanding applications and facilitating commercial deployment.