Conventional plastics are materials with attractive properties but with low recyclability. They also persist in the environment. Furthermore, the plastic waste decomposes into microplastic, which pollutes the soil, the sea, and the air. Therefore new regulations restrict its use. The existing biodegradable materials suffer from inferior mechanical properties (such as starch) or low degradability that needs to be enhanced (e.g., PLA).

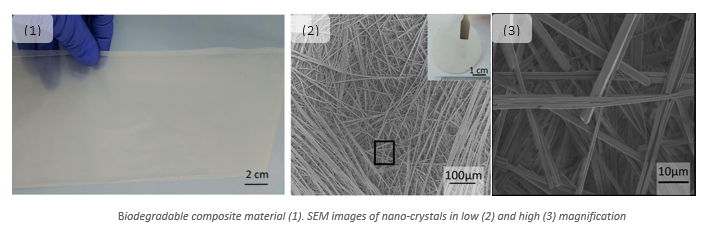

Prof. Rybtchinski and his group designed a biodegradable "fiberglass" composed of Nano-crystalline fibers and a biodegradable polymer. Both components are highly biodegradable, and the resulting composite material has properties akin to or better than known packaging plastics (which constitute 39% of all produced plastics).

Although plastics have superior properties, they are poorly recycled (~8%) due to a dramatic reduction of their properties in each recycle step. Plastic waste pollutes our soil, freshwater resources, atmosphere, and seas. As a prevention action, in the last few years, new regulations have been restricting the use of plastics to encourage alternatives such as reusable plastics or materials which decompose into biofriendly compounds by microorganisms (biodegradable materials). The main challenge of biodegradable materials is achieving regular plastics' mechanical properties while achieving high biodegradability.

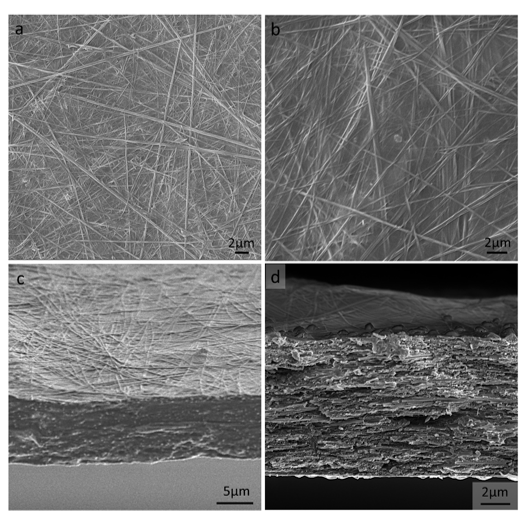

A fiberglass-like composite material was prepared out of Nano-crystals (the fibers) and a polymer, which are both highly biodegradable. This material has comparable properties to the commonly used packaging plastics; it exhibits including a high modulus (1000 MPa), tensile strength (70 MPa), elongation (55%), and toughness (25 MPa).

Both Nano-crystals and the biocompatible polymer are cheap products that can be manufactured from bioresources on a large scale. The Nano-crystals are used for reinforcement of the polymer.

Applications

- Biodegradable Packaging

Advantages

- Highly biodegradable (fast degradation in soil)

- Very cheap components

- Non-Toxic ingredients and product

- Simple to process

Initial prototypes demonstrated—scaling-up in progress.

This biodegradable "fiberglass" can be used for the packaging industry (39% of all plastics) due to its inexpensiveness and mechanical properties.

SEM images of the composite:

Dr. Vered Pardo Yissar